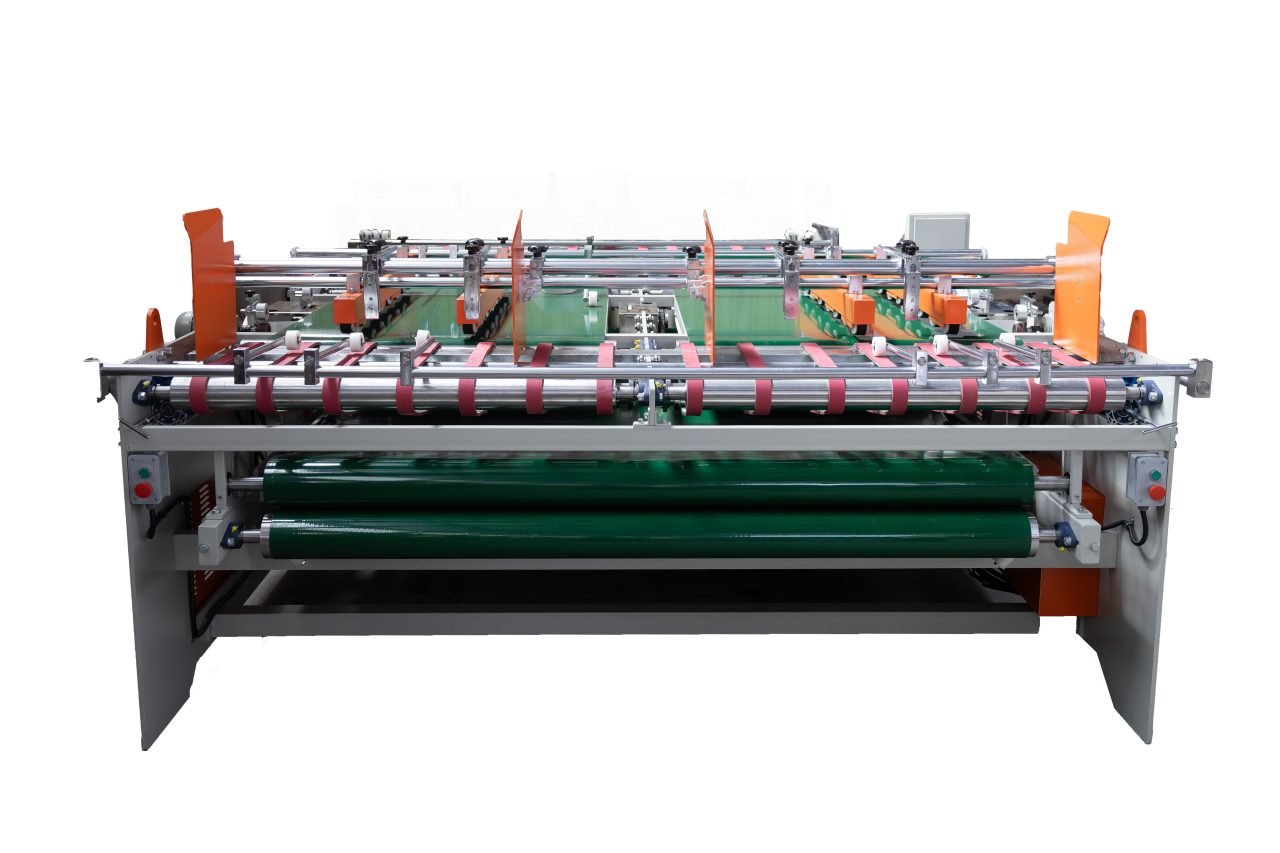

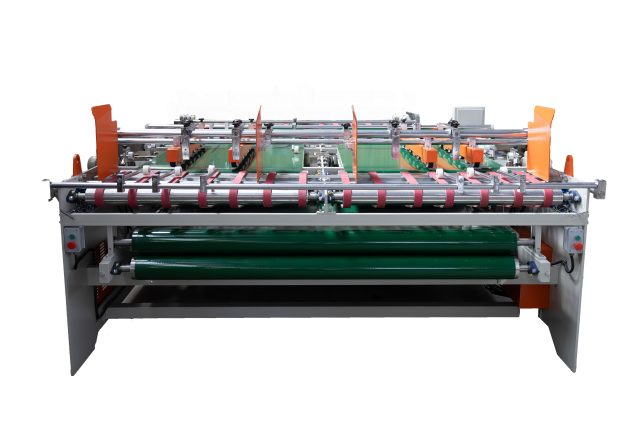

Packaging with a Semi-Automatic Folder Gluer (Two Lines) can make all the difference. Whether you’re scaling up production or streamlining your workflow, investing in the right technology is key — and that’s where this machine comes in.

In this in-depth guide, we’ll walk you through the benefits, features, comparisons, and usage tips of this incredible packaging solution — all in a friendly tone that even beginners can enjoy.

What You’ll Learn in This Guide

- What a semi-automatic folder gluer (two lines) is

- How it works and where it’s best used

- Its advantages over manual and fully automatic options

- Maintenance tips to maximize its lifespan

- How businesses are using it to grow fast

- And why Modern Machinee’s version might be the best one for your operations

Understanding the Packaging with a Semi-Automatic Folder Gluer

What Is a Folder Gluer?

A folder gluer is a machine designed to fold and glue paperboard or corrugated board into boxes. It’s a core part of many packaging lines — especially in industries like food, cosmetics, electronics, and more.

Semi-Automatic: What Does That Mean?

Semi-automatic means the machine handles most of the folding and gluing automatically, but requires manual loading of materials. It’s the perfect balance between cost and performance — great for small to mid-sized production runs.

Why Two Lines?

The “two lines” feature means the machine can work on two products at once. This boosts productivity, saves time, and reduces bottlenecks — especially useful if you deal with high-mix, low-volume production.

Key Benefits of Using a Semi-Automatic Folder Gluer (Two Lines)

1. Time-Saving

Compared to manual labor, this machine can process boxes much faster. Even with the semi-automatic model, you’ll easily double or triple your packaging output.

2. Cost-Efficient

While not as expensive as fully automatic machines, this one gives you the most value for your money. It cuts labor costs, improves consistency, and reduces errors.

3. Easy to Operate

You don’t need specialized training. The interface is intuitive, the setup is straightforward, and your team will quickly get the hang of it.

4. Versatile Usage

This model supports various box sizes and designs. Whether you’re packaging small electronics or large industrial goods, it’s got you covered.

5. Better Product Quality

Manual gluing often leads to inconsistent application, but this machine ensures a neat, uniform finish — which improves your product’s visual appeal and shelf presence.

How the Machine Works – Step-by-Step – Packaging with a Semi-Automatic Folder Gluer

Step 1: Loading the Material

Operators place flat box cutouts into the machine. The system allows two lines to be loaded simultaneously, cutting idle time in half.

Step 2: Folding Begins

Once inside, the machine folds flaps precisely according to the pre-programmed settings. Every box comes out exactly the same, with perfect angles.

Step 3: Glue Application

Glue is applied accurately using adjustable rollers or nozzles. You can control glue type, amount, and placement easily from the control panel.

Step 4: Output and Collection

Finished boxes exit the machine and are ready to be packed or filled. The dual-line setup means twice the output without needing extra space or manpower.

Who Should Invest in This Machine?

- Small factories looking to scale up production

- Packaging companies that need flexibility

- Brands needing faster box turnaround

- Startups that want automation without massive investment

If any of these sound like you, then Modern Machinee’s Semi-Automatic Folder Gluer (Two Lines) might be the smartest move for your business.

📦 Benefits of Using a Semi-Automatic Folder Gluer (Two Lines)

🚀 1. Faster Production with Fewer Hands

One of the biggest benefits of this machine is speed — not just in raw numbers, but in smart efficiency. Since it’s semi-automatic, it takes care of the tricky parts of folding and gluing, while your team handles the setup and placement. That means fewer people can get more done in less time.

Example:

If your manual team produces 1,000 boxes per shift, with the Semi-Automatic Folder Gluer (Two Lines), you might hit 2,000–2,500 easily with the same number of staff.

💰 2. Cut Down Labor Costs

In many packaging businesses, labor is one of the top 3 costs. This machine allows you to scale without having to double or triple your workforce. You save money while growing your capacity — win-win!

🤖 3. Reliable and Consistent Output

Manual work can lead to inconsistent results — crooked folds, missed glue lines, damaged flaps, and more. With this machine, every box looks like the one before it: professional and perfect. That consistency is essential for client satisfaction and brand trust.

🔄 4. Dual-Line Operation = Double the Output

Unlike a single-line machine, the two-line feature means it can handle two jobs at once. Whether it’s two types of cartons, or simply doubling the volume of one, you get unmatched flexibility.

🏭 Who Should Use This Machine?

This machine is ideal for businesses that:

- Produce medium to large volumes of cartons

- Want to upgrade from manual or outdated folder gluers

- Have multiple carton sizes and shapes to process

- Need a semi-automated solution without full industrial automation costs

If you’re a packaging supplier, e-commerce warehouse, printing company, or a carton box manufacturer, this machine is likely a strong fit.

📊 Comparing Folder Gluers – Manual vs Semi-Auto vs Fully Auto

| Feature | Manual | Semi-Auto (2 Lines) | Fully Automatic |

|---|---|---|---|

| Labor Requirement | High | Medium | Low |

| Speed | Low | Medium to High | Very High |

| Cost | Low | Medium Investment | Very High |

| Flexibility | High | Very High | Medium |

| Learning Curve | Easy | Easy to Moderate | Complex |

| Maintenance Cost | Low | Medium | High |

👉 Takeaway:

Semi-Automatic Folder Gluers (Two Lines) strike the perfect balance between speed, cost-efficiency, and flexibility. You get most of the automation benefits without the full cost and complexity of industrial systems.

🛠 What to Look for When Buying a Semi-Automatic Folder Gluer

Buying the right machine isn’t just about specs — it’s about finding the one that fits your workflow, team, and business model. Here’s what to keep in mind:

✅ 1. Build Quality & Durability

Look for a sturdy frame, premium rollers, and long-life belts. Machines like those from Modern Machinee are known for their build quality, even in tough environments.

⚙️ 2. Adjustability

You want a machine that can handle different carton sizes and styles — from straight-line to crash-lock cartons. Make sure the guides, belts, and folding mechanisms are easily adjustable.

⚡️ 3. Ease of Operation

No need to hire engineers to run it. Look for a user-friendly control panel, quick setup times, and intuitive adjustments.

🔧 4. After-Sales Support

Don’t underestimate the value of good support. Ask about training, spare parts availability, and remote/onsite troubleshooting options.

🔧 Maintenance Tips for Your Semi-Automatic Folder Gluer (Two Lines)

🧽 1. Daily Cleaning Checklist

A clean machine is a happy machine! At the end of each shift:

- Wipe down glue rollers

- Remove dust or carton bits from belts

- Check and clean sensors

- Clear glue nozzles (if applicable)

Just 10 minutes of cleaning a day can save you hours (or even days) of costly downtime.

🛢 2. Lubrication Matters

This isn’t a one-time job. Check the lubrication schedule in your machine’s manual. Bearings, chains, and belts need attention every few weeks — depending on usage.

💡 Pro Tip:

Set a reminder every 15 days for a quick lube check. Preventative care always beats emergency repairs.

🧰 3. Inspection Routine

Once a week, do a quick inspection of:

- Belt tension

- Roller alignment

- Air compressor (if attached)

- Glue system pressure

If you spot early wear or loosening, you can fix it before it becomes a major problem.

🧠 How to Maximize the Life and ROI of Your Machine

📏 Train Your Operators Right

Even the best machine fails when it’s handled poorly. Make sure every operator understands:

- Proper startup and shutdown

- Changing box sizes

- Emergency stops and safety checks

- Basic troubleshooting

You don’t need specialists — just clear, simple training (which Modern Machinee offers at delivery).

📦 Use Quality Consumables

Cheap glue or poor-quality cartons can cause jams, wear out belts faster, or mess with sensors. Use quality supplies that match the machine’s standards.

🛠 Schedule Annual Servicing

A once-a-year full check-up keeps the machine tuned. Partner with your supplier for annual maintenance — it’s a small cost compared to big breakdowns.

🌟 Real-World Success Stories

📍 Case Study 1: Small Packaging Firm in Muscat

Before: Manual folding, 3 employees, ~600 boxes/shift

After: Installed Semi-Auto Folder Gluer (Two Lines)

Result: 1,800 boxes per shift with 2 operators — 3X output, same floor space!

“We couldn’t afford a fully automated line, but this machine gave us nearly the same results. Total game changer!” — Khalid, Packaging Supervisor

📍 Case Study 2: E-Commerce Business in Sohar

Problem: Growing online orders but slow packaging times

Solution: Semi-Auto Folder Gluer added to their warehouse

Impact: Faster order fulfillment, reduced delays, and better customer reviews

“We now fold and glue boxes in-house instead of buying them ready-made. It cut packaging costs by over 30%.” — Sarah, Operations Manager

📞 Want to See What It Can Do For You?

If you’re curious about how a Semi-Automatic Folder Gluer (Two Lines) can fit into your business, reach out to the experts at ModernMachinee.com — or click here to view full specs, photos, and pricing.

🔮 The Future of Folder Gluing — What’s Coming in 2025 and Beyond?

🚀 1. Smarter Machines with IoT Integration

Even semi-automatic machines are getting smarter. Manufacturers are starting to:

- Add basic IoT modules for performance tracking

- Offer remote diagnostics

- Enable cloud-based maintenance logs

This means less downtime and faster troubleshooting — even in budget-friendly models.

🤖 2. AI-Assisted Setup and Adjustment

While full AI integration is still reserved for high-end lines, semi-automated machines are now including:

- Auto-belt alignment sensors

- Glue flow optimization suggestions

- Error pattern analysis

These upgrades reduce operator dependency and lower skill barriers.

🌍 Sustainability Is the New Standard

Eco-conscious businesses are now expecting packaging machinery that helps them:

- Reduce glue waste

- Optimize carton design (to minimize material use)

- Lower electricity consumption

Modern Machinee’s Semi-Automatic Folder Gluer is energy-efficient and designed to work with biodegradable glues and recyclable cartons.

🥇 Why This Machine Will Keep You Competitive

✅ Lower Overhead, Higher Output

You don’t need a massive automation budget to scale. This machine gives you:

- Competitive production speed

- Affordable entry cost

- Flexibility across different box styles

💼 Perfect for Oman’s Small & Mid-Sized Enterprises

Whether you’re in Muscat, Salalah, or Sohar — Oman’s growing manufacturing sector is hungry for cost-efficient, scalable solutions. This machine hits the sweet spot between manual labor and full automation.

🛒 How to Order the Semi-Automatic Folder Gluer (Two Lines)

📋 What You Get:

- 2-Line Output (Dual Efficiency)

- Local Support in GCC

- Full Operator Training

- 1-Year Warranty + Spare Parts

📞 Ready to upgrade your packaging line?

👉 Visit modernmachinee.com/product/semi-automatic-folder-gluer-two-line

or

📩 Contact us via WhatsApp or Email for a free quote.

✍ Final Words

The Semi-Automatic Folder Gluer (Two Lines) is not just a machine — it’s your partner in growth. It helps you:

- Triple your box production

- Reduce labor cost

- Maintain flexibility

- Stay competitive in 2025 and beyond

Don’t wait for the perfect moment — build your packaging advantage today.