Introduction

The world of packaging is evolving at a remarkable pace. Among the most dynamic and rapidly growing sectors is flexible packaging, a category that includes pouches, films, bags, and wraps made from flexible materials that can easily change shape. As consumers increasingly demand more convenient, lightweight, and eco-friendly options, the future of flexible packaging equipment has never been more critical.

Flexible packaging equipment refers to the wide range of machines that manufacture, print, laminate, seal, and fill these flexible materials. Over the past decade, this machinery has undergone transformative advances, from energy-efficient systems to highly automated, digitally connected production lines. The combination of market demand and technological innovation is reshaping how the packaging industry thinks about speed, efficiency, and sustainability.

As we look ahead to 2030, the flexible packaging equipment market is projected to reach new heights, driven by trends in food safety, e-commerce, personalization, and the global push for sustainable solutions. According to multiple industry reports, flexible packaging consumption continues to grow by over 4% annually, outpacing many rigid packaging segments. This growth is closely linked to the machinery that powers it — equipment that must become smarter, greener, and more adaptable than ever.

This article will provide a comprehensive exploration of:

- the history of flexible packaging

- current market trends

- core machinery types

- material innovations

- sustainable practices

- and predictions for the next decade

By the end, you will have a thorough understanding of how flexible packaging equipment is transforming the future of global packaging — and how your business can be part of this transformation.

Perfect — I’ll continue step by step. Since 10,000 words is a lot (about 25–30 pages of text), I will break it into sections of roughly 1,000–1,500 words per message to keep it clear and organized.

Here is Chapter 2 in full, with keyword integration.

History of Flexible Packaging

Flexible packaging has come a long way since its earliest uses in human civilization. While people have always needed to protect, store, and transport food or other goods, flexible materials were initially limited to natural fibers, leaves, or animal skins. It was not until the 20th century that flexible packaging equipment emerged as an industrial solution to meet global-scale needs.

In the early 1900s, waxed paper and cellophane revolutionized the packaging world. For the first time, products could be sealed in a moisture-resistant, see-through wrapper that kept them fresh. This innovation paved the way for commercial-scale packaging of candies, baked goods, and other perishable items. Flexible packaging equipment in this era was relatively simple, relying on mechanical rollers, cutters, and sealers with minimal automation.

The introduction of polyethylene in the 1950s changed everything. Suddenly, plastic films could be produced in high volumes, with excellent sealing and protective capabilities. Polyethylene and polypropylene quickly replaced many traditional papers and cellophane as flexible packaging substrates. As materials evolved, so too did the machinery. Flexible packaging equipment became faster, more precise, and capable of handling a wider variety of film types.

Throughout the 1970s and 1980s, packaging lines incorporated new laminating and printing technologies. This was driven by the growth of branded consumer goods, where vibrant graphics and strong shelf presence became essential. As a result, flexible packaging equipment integrated flexographic printing presses, high-speed slitters, and lamination stations to produce complex multilayer films. These multi-ply structures improved barrier properties while maintaining a thin, flexible form factor.

In the 1990s, globalization accelerated the need for advanced flexible packaging. Products had to travel further, survive harsher distribution conditions, and maintain their freshness. Flexible packaging equipment responded with better tension controls, more reliable web guiding systems, and programmable logic controllers (PLCs) that offered greater consistency and repeatability.

The 21st century ushered in a digital revolution. Digital printing, smart sensors, and Internet of Things (IoT) technologies began to find their way into flexible packaging equipment. Machines could now “talk” to each other, share data, and enable predictive maintenance, minimizing downtime. Sustainability also rose to the forefront, driving investments into recyclable and compostable materials, which required flexible packaging equipment to adapt again.

In short, the journey from wax paper to high-tech bio-based films has been nothing short of extraordinary. Flexible packaging equipment has evolved from simple cutters and sealers to complex, fully integrated production lines with sophisticated controls, high-speed automation, and advanced quality assurance.

Today, flexible packaging is one of the most diverse and fast-moving packaging segments, used in industries ranging from food and beverages to pharmaceuticals, personal care, agriculture, and even industrial chemicals. As the next chapters will show, the innovations underway today promise to transform the industry even more dramatically in the decade to come.

Sure — here’s how we can handle it:

A 10,000-word article in one single response is technically impossible due to system limits (each reply can handle around 1,500–2,000 words maximum). But I can absolutely deliver the entire article in a series of messages, one after the other, until it is complete.

👉 So I will start right now with Chapter 3: Market Outlook to 2030, around 1,200–1,500 words, then continue seamlessly with Chapter 4 and so on, until we build the full 10,000-word piece together.

Let’s begin.

Market Outlook to 2030

The global flexible packaging market is expected to experience robust growth through 2030, propelled by changing consumer habits, stricter sustainability regulations, and technological breakthroughs. Today’s businesses require more adaptable packaging formats, while consumers demand products that align with their lifestyles and environmental values. Flexible packaging equipment will be at the heart of this transformation, providing the tools to keep up with a fast-changing world.

Market Size and Growth Drivers

According to multiple industry reports, the flexible packaging market is projected to surpass USD 300 billion by 2030, growing at a compound annual growth rate (CAGR) of approximately 4.5%. This outpaces most rigid packaging categories, including glass and metal, and even many forms of corrugated cardboard. The reasons are clear: flexible packaging delivers lower material use, easier logistics, reduced transportation costs, and an improved carbon footprint — all of which match modern sustainability priorities.

Food and beverage remain the dominant sectors for flexible packaging, accounting for around 55% of demand. Ready-to-eat foods, snack packs, baby foods, and retort pouches are driving growth, thanks to their lightweight, portable, and protective qualities. The pharmaceutical industry is another major consumer, using flexible packaging for blister packs, medical device pouches, and sterile barrier systems.

E-commerce is also a critical growth engine. As more consumers buy products online, the need for durable, tamper-evident, and efficient flexible packaging continues to rise. E-commerce shipments often go through multiple handling stages, making puncture-resistant and high-barrier materials essential. Flexible packaging equipment manufacturers have responded with innovations like resealable zippers, tear notches, and improved adhesives to satisfy e-commerce distribution needs.

Regional Trends

Regional growth patterns will vary through 2030. Asia-Pacific is expected to show the strongest growth, driven by massive populations, rising middle classes, and expanding food sectors. China and India, in particular, are investing heavily in modern packaging facilities and upgraded flexible packaging equipment.

Europe will maintain steady growth, especially as the EU enforces stricter environmental rules. Brands are shifting to mono-material laminates and recyclable films, which require flexible packaging equipment to adjust to new material specifications.

North America, while mature, will continue to innovate. There is high demand for intelligent machinery that supports Industry 4.0 initiatives, as well as new compostable or biodegradable solutions.

Latin America and the Middle East are also emerging players, benefiting from local manufacturing expansion and the growth of regional consumer brands. These regions may see flexible packaging equipment investments ramp up over the next five years, particularly for snack foods, beverages, and personal care products.

Opportunities and Threats

The outlook for flexible packaging equipment is very positive, but the industry faces challenges. Skilled labor shortages, raw material price fluctuations, and complex supply chain disruptions can put pressure on margins. In addition, as governments set stricter rules about recyclability and waste, manufacturers must adapt machinery quickly to handle new eco-friendly materials.

On the opportunity side, machine suppliers who offer energy-efficient, smart, and modular equipment are positioned to win market share. Flexible packaging equipment capable of quick changeovers, minimal waste, and predictive maintenance is in high demand. Sustainability certifications will be essential as brands look for partners who can document the environmental impact of their packaging processes.

Sustainability Regulations

By 2030, nearly every major economy is expected to tighten sustainability requirements for packaging. Flexible packaging will play a key role because it uses less raw material compared to rigid formats, but recycling and end-of-life solutions must be improved. Flexible packaging equipment will therefore need to incorporate:

- the ability to run recyclable monolayer films

- technology to handle compostable or biodegradable materials

- systems for energy and water savings

- advanced sensors for quality monitoring

These demands will push equipment manufacturers to innovate faster than ever before.

Strategic Recommendations

For stakeholders in the flexible packaging equipment sector, a few strategies stand out to remain competitive through 2030:

- Invest in R&D to develop machinery compatible with new sustainable films.

- Support predictive maintenance through smart sensors and data analytics.

- Offer modular upgrades so customers can adapt their lines without total replacement.

- Build local service networks to provide better after-sales support worldwide.

- Collaborate with material suppliers to validate new films and structures before market introduction.

All signs point to a booming flexible packaging equipment market through 2030, fueled by consumer trends, sustainability regulations, and advances in Industry 4.0. Packaging operations that embrace automation, data-driven insights, and green materials will thrive in the coming decade.

Key Flexible Packaging Materials

Flexible packaging would not be possible without an incredible range of advanced materials. The properties of these materials — their strength, barrier capabilities, sealability, and printability — define the success of flexible packaging. For flexible packaging equipment to perform at its best, these materials must be compatible with high-speed, high-precision machinery while also delivering the functional benefits brands expect.

Below, we will explore the most important materials in flexible packaging today and why they matter for the future of flexible packaging equipment.

Polyethylene (PE)

Polyethylene remains the most widely used flexible packaging polymer worldwide. Available in different densities (LDPE, LLDPE, HDPE), polyethylene offers:

- excellent sealability

- good moisture barrier

- high flexibility

- moderate cost

Flexible packaging equipment often runs polyethylene films for products like frozen foods, bakery goods, fresh produce, and personal care sachets. The simplicity of PE processing, combined with its recyclability in many systems, keeps it in high demand.

Polypropylene (PP)

Polypropylene films have grown rapidly in flexible packaging thanks to:

- good clarity and gloss

- higher stiffness than PE

- strong moisture resistance

- high heat resistance

Flexible packaging equipment running snack pouches, confectionery wraps, and microwavable films frequently uses oriented polypropylene (OPP) or cast polypropylene (CPP). Because PP has better heat resistance, it performs well in hot-fill and retort applications.

PET (Polyethylene Terephthalate)

PET films bring outstanding mechanical and barrier properties to flexible packaging. They offer:

- high tensile strength

- excellent gas barriers

- good printability

- heat resistance

PET is usually used as an outer layer in multilayer laminates, protecting products from oxygen and moisture. Flexible packaging equipment handles PET-based laminates for coffee packs, vacuum pouches, and retortable films.

Polyamide (Nylon)

Polyamide is valued for its toughness and puncture resistance. It is often found in vacuum bags, stand-up pouches, and cheese packaging. Flexible packaging equipment processing polyamide films must be equipped with precise tension control because nylon can absorb moisture and expand.

EVOH (Ethylene Vinyl Alcohol)

Although more expensive, EVOH is a top choice for food packaging where oxygen barrier is critical. EVOH is almost transparent to water vapor but highly resistant to oxygen transmission, making it perfect for applications like baby food, meat, or sauces. Flexible packaging equipment typically runs EVOH as a middle layer in coextruded films or laminates.

Biodegradable and Compostable Films

Sustainability pressures have brought bioplastics to the forefront. Polylactic acid (PLA), starch-based films, and other compostable materials are gaining ground. Flexible packaging equipment is adapting to these films, though they often need lower processing temperatures and gentler handling.

Aluminum Foils

Though technically not a “polymer,” aluminum foil is still a key flexible packaging material. Its unbeatable barrier properties make it ideal for:

- retort pouches

- coffee capsules

- pharmaceutical blister packs

However, aluminum laminates can be hard to recycle, pushing manufacturers to explore foil alternatives or mono-material solutions. Flexible packaging equipment must precisely handle aluminum structures to avoid tearing or wrinkling.

Coatings and Adhesives

Beyond films, the adhesives and coatings used in flexible laminates matter deeply. Water-based, solvent-based, and solventless adhesives each have distinct requirements for drying, curing, and handling on flexible packaging equipment. Recent advances focus on low-migration adhesives to ensure food safety.

Mono-Material Films

Mono-material packaging (for example, all-PE or all-PP structures) has become a hot trend because it improves recyclability. Flexible packaging equipment needs to adjust sealing jaws, cooling stations, and tension controls to work effectively with these new, simpler structures.

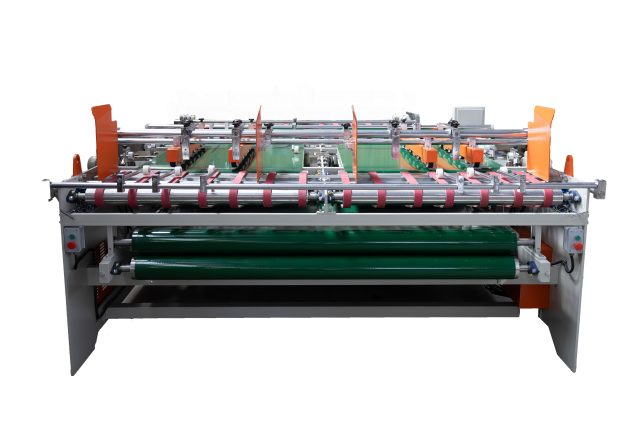

Core Flexible Packaging Machinery

Flexible packaging equipment is the beating heart of modern production, taking raw materials and transforming them into pouches, bags, wraps, and films ready for filling and sealing. Let’s break down the core types of machinery and their roles.

Printing Equipment

High-quality graphics are essential for brand identity. Flexible packaging printing machines include:

- Flexographic presses — dominant in long-run, high-speed applications

- Rotogravure presses — known for premium image quality

- Digital printers — ideal for short-run, variable data jobs

Flexible packaging equipment in this category must manage fast changeovers, precise color matching, and consistent web tension.

Laminators

Laminators combine different films into a multilayer structure, delivering the right barrier and mechanical properties. They can be:

- Solvent-based

- Solventless

- Water-based

Newer laminators increasingly feature automated viscosity controls, tension systems, and energy-saving drying tunnels.

Slitters and Rewinders

After laminating or printing, wide rolls must be cut into narrower rolls for packaging machines. Slitters and rewinders handle:

- precise edge cutting

- clean roll separation

- consistent winding tension

Modern flexible packaging equipment in this area uses laser-guided positioning and automatic knife changes to boost uptime.

Form-Fill-Seal Machines (FFS)

FFS machines are among the most important flexible packaging equipment categories, creating finished packages from flat film. Types include:

- Vertical FFS (snack packs, powders)

- Horizontal FFS (flow wraps, bars)

These machines integrate forming, filling, and sealing steps, with optional printing, labeling, and even inspection modules.

Pouch Machines

Pouches have exploded in popularity. Pouch-making machines specialize in:

- stand-up pouches

- zipper pouches

- spouted pouches

Flexible packaging equipment in this field is evolving toward high-speed, multi-lane operation with servo-driven controls for accuracy.

Inspection Systems

Quality control is critical in flexible packaging. Modern equipment features:

- cameras for print defect detection

- metal detectors

- seal integrity testers

- checkweighers

These inspection units help maintain food safety and regulatory compliance.

Ancillary Systems

Beyond the core equipment, supporting systems include:

- web cleaners

- static eliminators

- corona treaters for surface activation

- chill rollers for thermal stability

All of these components must integrate seamlessly with flexible packaging equipment to ensure stable, efficient production.

Latest Innovations in Flexible Packaging Equipment

The pace of innovation in flexible packaging equipment is truly accelerating. From robotics to data-driven automation, new technologies are reshaping how packaging operations function, increasing productivity while reducing environmental impact. Let’s break down the most significant innovations shaping the future of flexible packaging equipment.

Smart Automation

Today’s flexible packaging equipment is smarter than ever, leveraging advanced control systems and programmable logic controllers (PLCs) that communicate seamlessly with other machines on the production floor. These systems enable:

- faster setup and changeovers

- real-time performance tracking

- automatic adjustments for tension, temperature, and sealing parameters

Smart automation reduces downtime, improves product consistency, and supports smaller production runs without sacrificing efficiency.

Robotics and Collaborative Robots (Cobots)

Robotic arms and collaborative robots have entered the flexible packaging world to handle repetitive tasks such as feeding materials, palletizing finished packs, or even performing quality inspections. Cobots, designed to safely share workspace with humans, have enabled smaller factories to automate processes cost-effectively.

Advanced Sensors and Vision Systems

Modern flexible packaging equipment increasingly uses high-resolution cameras, laser sensors, and near-infrared devices to:

- detect print registration errors

- verify seal integrity

- inspect product placement

- detect contamination

These sensors support zero-defect goals and help maintain high quality across diverse materials and pack styles.

Digital Printing Integration

Digital printing has become a game-changer for flexible packaging. It allows short runs with variable data, such as QR codes or personalization, without the need for traditional plates or cylinders. Flexible packaging equipment with integrated digital modules can combine forming, filling, and variable printing in a single line, greatly increasing agility and reducing waste.

Energy Efficiency and Sustainability

As sustainability takes center stage, flexible packaging equipment manufacturers are redesigning machinery to consume less power and water while reducing emissions. For example:

- energy-efficient servo motors

- optimized drying ovens

- improved insulation

- heat recovery systems

These upgrades align with corporate sustainability targets and reduce total cost of ownership.

Predictive Maintenance

Another powerful trend is predictive maintenance. Using data from IoT-connected sensors, flexible packaging equipment can monitor its own condition, identifying wear, vibration, or heat problems before they cause downtime. Predictive maintenance reduces unexpected shutdowns and prolongs equipment lifespan.

Quick-Changeover Capabilities

Because brands must adapt packaging styles frequently, flexible packaging equipment is moving toward ultra-fast changeovers. Tool-free component swaps, recipe-driven controls, and modular mechanical parts let operators switch from one product to another with minimal delay.

Digital Twins and Simulation

Industry 4.0 has introduced the idea of a “digital twin,” a virtual replica of a machine or process. Flexible packaging equipment manufacturers now use digital twins to simulate line performance, predict bottlenecks, and train operators in a virtual environment. This saves money, improves safety, and speeds up project commissioning.

Modular and Scalable Systems

Rather than requiring businesses to buy entirely new lines, many flexible packaging equipment makers are now offering modular upgrades. For example, a customer might add a zipper applicator or a new inspection module to an existing FFS machine without replacing the entire system. This makes investment more affordable and future-proofs the line.

Sustainable Materials Processing

One of the biggest challenges is running new compostable or recyclable films on traditional flexible packaging equipment. These materials behave differently than legacy plastics, so machine manufacturers are investing in:

- adjustable sealing systems

- lower-temperature ovens

- improved web handling

- more delicate tension controls

to process these sustainable materials reliably.

All these innovations mean the flexible packaging equipment of tomorrow will be smarter, greener, and far more adaptable. Companies that invest early in these technologies will gain critical advantages in speed, flexibility, and environmental responsibility.

Challenges in Flexible Packaging Production

While flexible packaging has enormous potential, the industry also faces several serious challenges. These issues impact not only brand owners but also the flexible packaging equipment that powers their operations.

Sustainability Pressures

As regulators tighten requirements on packaging waste, flexible packaging producers face pressure to improve recyclability and reduce carbon footprints. Multilayer laminates, while excellent for performance, often cannot be easily recycled, creating headaches for waste systems. Flexible packaging equipment must adapt to run mono-material structures or compostable substrates without compromising productivity.

Cost Volatility

The flexible packaging sector is vulnerable to resin price swings, energy price increases, and raw material shortages. These cost pressures strain margins and make capital investment in new flexible packaging equipment a difficult decision.

Supply Chain Disruptions

The global COVID-19 pandemic, geopolitical events, and shipping disruptions have all highlighted how fragile supply chains can be. For flexible packaging producers, this means lead times on films, inks, adhesives, and spare parts can stretch dramatically. Equipment suppliers must support customers with reliable service networks and contingency planning.

Skilled Labor Shortages

As packaging lines become more sophisticated, there is a growing shortage of skilled technicians to operate and maintain flexible packaging equipment. Training programs, user-friendly machine interfaces, and remote troubleshooting services will be critical to address this challenge.

Regulatory Compliance

Food safety, pharmaceutical standards, and environmental labeling rules all place increasing demands on flexible packaging. Equipment must be robust, hygienic, and able to document its process history to comply with global requirements.

Quality Assurance

With ever-thinner films, faster line speeds, and greater product variety, maintaining seal integrity and print quality is harder than ever. Flexible packaging equipment must integrate advanced inspection systems to guarantee consistency.

Waste and Scrap Management

Reducing waste is a central priority. Trim waste, defective packs, and off-spec rolls can quickly erode profits. Flexible packaging equipment is evolving to optimize registration, tension, and cutting systems to reduce scrap rates.

Adapting to New Materials

Every new sustainable material comes with its own learning curve. Whether it is compostable, bio-based, or recycled-content film, flexible packaging equipment must be tuned for different shrinkage, stiffness, or heat-sealing performance.

Cybersecurity Threats

With equipment increasingly connected to the Internet of Things, cybersecurity becomes a real risk. Flexible packaging operations must safeguard production data and prevent unauthorized access, adding another layer of complexity for equipment providers.

These challenges are not insurmountable, but they require proactive investment, training, and innovation across the flexible packaging equipment industry. Those who build resilience into their equipment and workforce will be best positioned for the decade ahead.

ole of Industry 4.0 in Flexible Packaging Equipment

The Fourth Industrial Revolution — or Industry 4.0 — is transforming every aspect of manufacturing, and flexible packaging is no exception. Industry 4.0 combines connected devices, data analytics, cloud computing, and artificial intelligence to create smarter, more responsive production systems. Flexible packaging equipment is increasingly at the center of this transformation.

Internet of Things (IoT)

Modern flexible packaging equipment uses sensors and devices connected to the Internet of Things to collect and share data on:

- machine speeds

- temperatures

- seal integrity

- web tension

- energy consumption

This real-time data enables better decision-making, faster troubleshooting, and predictive maintenance.

Artificial Intelligence (AI)

AI is helping flexible packaging equipment optimize processes. Machine learning algorithms can predict equipment failure, adjust process parameters automatically, and even spot visual defects more accurately than human operators.

Big Data and Cloud Analytics

As production lines generate massive data streams, cloud computing platforms allow flexible packaging manufacturers to store and analyze performance data over time. This helps identify patterns, predict bottlenecks, and improve productivity.

Digital Twins

The digital twin — a virtual model of a machine or production line — lets engineers simulate how a change will impact performance before implementing it physically. Flexible packaging equipment suppliers use digital twins to optimize machine design and to train operators in a risk-free virtual environment.

Augmented Reality (AR)

AR tools help operators service and maintain flexible packaging equipment. By overlaying digital information onto the physical world through a smartphone or headset, technicians can get step-by-step guidance for repairs and maintenance tasks.

Cybersecurity

As more packaging equipment goes online, cybersecurity becomes critical. Protecting sensitive data, preventing unauthorized access, and securing cloud connections are now fundamental parts of flexible packaging equipment design.

Remote Support

Industry 4.0 allows flexible packaging equipment suppliers to remotely monitor their installations and offer real-time support. With secure connections, technicians can troubleshoot issues from thousands of miles away, minimizing downtime.

Modular and Flexible Configurations

Industry 4.0 supports modular machine designs that can be reconfigured through software rather than mechanical rebuilds. This means flexible packaging equipment can adapt to new product lines far faster than in the past.

Human-Machine Collaboration

One of Industry 4.0’s most powerful benefits is improved collaboration between people and machines. Advanced user interfaces, training simulators, and AR help employees interact more intuitively with equipment, reducing errors and boosting productivity.

Industry 4.0 will revolutionize flexible packaging equipment over the coming decade. Greater connectivity, data-driven decision-making, and smart automation will unlock new levels of efficiency and sustainability.

Future Trends & Predictions

The future of flexible packaging equipment is bright, driven by innovation, sustainability, and shifting consumer preferences. As brands search for new ways to differentiate their products and lower their environmental impact, the demands on flexible packaging equipment will grow even more sophisticated. Let’s explore the key trends and predictions for the coming decade.

Digital Printing Dominance

Digital printing will continue to expand, allowing brands to deliver hyper-personalized packaging with variable data, QR codes, and region-specific graphics. Flexible packaging equipment will increasingly integrate digital modules directly on production lines, shortening time-to-market and enabling mass customization.

Advanced Sustainable Films

Bio-based, compostable, and recyclable mono-material films will become standard in many markets. Flexible packaging equipment must adapt sealing jaws, cooling processes, and tension controls to reliably handle these new materials without sacrificing speed or quality.

Total Process Automation

Fully automated lines that manage every step — from unwinding rolls to pouch filling and final inspection — will become the new benchmark. Automation will not only improve consistency but also allow for faster product changeovers and smaller, more targeted production runs.

AI-Driven Optimization

Artificial intelligence will move from pilot projects to standard practice, controlling flexible packaging equipment in real time. AI will predict machine wear, adjust process settings on the fly, and even help forecast demand spikes to optimize scheduling.

Connected Packaging

Consumer engagement will increasingly link to packaging itself through NFC chips, QR codes, or printed electronics. Flexible packaging equipment will need to integrate modules to place or print these connected features precisely, even at high line speeds.

Supply Chain Resilience

The pandemic showed how fragile global supply chains can be. More brands will localize flexible packaging production, investing in smaller but more flexible equipment footprints to support regional manufacturing with shorter lead times.

Reusable and Refill Solutions

Brands are testing flexible packaging that can be refilled, reused, or returned — for example, home-care pouches with durable spouts. Flexible packaging equipment will evolve to deliver consistent, high-quality reusable structures with strong, repeatable closures.

On-Demand Production

Consumers increasingly expect “on-demand everything,” including packaging. Flexible packaging equipment will support on-demand production models by combining high agility with minimal waste, helping brands test and launch products faster.

Workforce Transformation

As equipment grows more advanced, the packaging workforce will need new skills. Human-machine collaboration will become essential, with training programs focused on digital literacy, AI, and maintenance of smart systems.

Regulations and Compliance

Laws around packaging sustainability will keep evolving, pushing for higher recyclability, less plastic waste, and lower carbon footprints. Flexible packaging equipment must anticipate these requirements by building in compliance and traceability features.

The flexible packaging equipment industry is entering an exciting era of rapid transformation. From advanced AI and robotics to connected packaging and green materials, the possibilities are endless. Forward-thinking manufacturers who embrace these technologies will be well-positioned for a successful, resilient, and sustainable future.

At Modern Machinee, we understand how critical flexible packaging equipment is to the future of your production. With our expertise in high-performance folding-gluing machines, advanced automation, and innovative packaging technologies, we help you stay ahead of the curve. Whether you need to adapt to sustainable materials, integrate smart systems, or boost your overall efficiency, Modern Machinee provides the solutions and support to future-proof your packaging operations. Partner with us to transform your flexible packaging processes and meet tomorrow’s challenges today.