Introduction

The global packaging industry is undergoing a fundamental transformation as we move through 2025. The forces driving these changes are multifaceted—ranging from environmental challenges and technological innovation to changing consumer preferences and shifting regulations. Packaging is no longer just a protective shell for products; it is an integral part of brand identity, customer experience, and operational efficiency. At the heart of this transformation are the Packaging Trends 2025, a collection of key developments shaping how businesses approach design, production, sustainability, and logistics. This article delves into the top trends that are redefining the packaging landscape, offering insights and strategies for companies looking to stay ahead of the curve and remain competitive in a rapidly evolving marketplace.

1. Sustainable Packaging Becomes the New Normal

One of the most dominant Packaging Trends 2025 is the continued push toward sustainability. As climate change concerns intensify, both consumers and regulators are demanding greener alternatives to traditional packaging. This has resulted in a surge in demand for recyclable, biodegradable, and compostable materials. Brands are experimenting with materials such as PLA (polylactic acid), PHA (polyhydroxyalkanoates), seaweed-based packaging, and even edible films. These innovations aim to reduce waste, lower carbon emissions, and minimize the environmental footprint of products throughout their lifecycle.

Moreover, the emphasis on sustainable packaging extends beyond material choices. Companies are adopting minimalistic design strategies that reduce excess materials, lower ink usage, and create more efficient packaging structures. Smart logistics, like flat-pack packaging and right-size boxes, are helping reduce transportation emissions and warehouse storage costs. Meanwhile, regulations like Extended Producer Responsibility (EPR) laws are holding companies accountable for the end-of-life impact of their packaging, encouraging investments in reuse and recycling infrastructure.

Sustainability is no longer a niche concern—it is a critical component of brand trust and long-term competitiveness. Companies that embrace this Packaging Trends 2025 movement are not only meeting regulatory requirements but also appealing to the growing segment of environmentally conscious consumers who reward ethical and transparent brands.

2. Automation and Smart Packaging Technology

As labor shortages, rising costs, and demand for speed increase across the global supply chain, automation has become one of the defining Packaging Trends 2025. Automation technologies in packaging lines—from robotic arms and smart conveyors to machine learning-enabled quality control—are improving consistency, reducing errors, and enhancing throughput. By automating repetitive and labor-intensive tasks, companies are freeing up resources to focus on innovation and customer satisfaction.

Smart packaging technologies are also gaining momentum. These include RFID tags, QR codes, NFC chips, and sensors that provide real-time data on product conditions such as temperature, humidity, and freshness. This is particularly important in industries like food, pharmaceuticals, and luxury goods, where traceability and authenticity are critical. Connected packaging allows for better inventory management, enhanced product safety, and interactive experiences for consumers.

With artificial intelligence (AI) becoming more accessible, data-driven decision-making is empowering brands to fine-tune their packaging strategies. Predictive analytics can optimize material use, forecast demand, and reduce supply chain risks. Overall, automation and smart packaging are no longer futuristic concepts—they are integral components of the modern packaging ecosystem.

3. Personalization and Digital Printing

One of the most consumer-centric Packaging Trends 2025 is the rise of personalization through digital printing. With consumers expecting unique, meaningful interactions with brands, packaging is playing a pivotal role in delivering customized experiences. Advances in digital printing technology allow brands to tailor packaging at scale—offering limited-edition designs, localized artwork, or personalized messages without increasing production costs.

This trend is especially popular in industries like cosmetics, beverages, and e-commerce, where packaging often doubles as a gift or marketing tool. The ability to print variable data, incorporate customer names, or even create interactive experiences with augmented reality (AR) elements fosters stronger emotional connections and boosts brand loyalty.

Digital printing is also accelerating go-to-market timelines, allowing for faster prototyping and reduced inventory waste. Instead of large production runs that risk obsolescence, companies can produce just-in-time packaging in small batches based on real-time market feedback. As technology becomes more accessible, digital printing will continue to empower even small businesses to compete on creativity and customer engagement.

4. Flexible Packaging Solutions

Among the rising Packaging Trends 2025, flexible packaging is gaining attention for its lightweight, cost-effective, and consumer-friendly nature. From stand-up pouches to resealable zip locks, flexible packaging reduces waste, minimizes transport costs, and improves product shelf life. Its adaptability makes it ideal for a wide range of sectors including food, personal care, pharmaceuticals, and pet products.

With consumers demanding convenience and portability, flexible packaging offers a strong value proposition. Its efficient barrier properties also support product preservation while reducing environmental impact. Innovations in mono-material films and recyclable laminates are helping bridge the gap between flexibility and sustainability.

Businesses that adopt flexible packaging strategies not only meet consumer demands but also position themselves as forward-thinking and resource-efficient players in a competitive landscape.

5. E-commerce and Omnichannel Packaging Optimization

The boom in online shopping has brought with it a new set of challenges and opportunities for packaging. Packaging Trends 2025 emphasize optimizing packaging for omnichannel fulfillment—from direct-to-consumer shipments to traditional retail. E-commerce packaging must balance protection, branding, and cost-efficiency.

Right-sizing, frustration-free unboxing, tamper-evidence, and returns-ready packaging are becoming standard practices. Smart inserts and branded interior design are also enhancing customer experience while reducing packaging waste. Companies are using digital twins and simulation software to test packaging in virtual environments before physical deployment.

As e-commerce continues to evolve, companies that align their packaging strategies with omnichannel logistics will see improvements in operational efficiency, customer satisfaction, and sustainability metrics.

6. Circular Economy and Reusable Packaging Models

The transition to a circular economy is at the heart of the Packaging Trends 2025. Businesses are exploring reusable packaging systems, refillable containers, and take-back schemes that keep materials in circulation longer. This shift not only addresses waste reduction but also fosters deeper customer relationships.

Reusable packaging is gaining traction in industries like groceries, fashion, and B2B logistics. Services like Loop and other refillable programs are proving that consumers are willing to participate in circular models when incentivized properly. Digital tools like QR codes and tracking platforms enhance transparency and accountability.

Companies that embrace reuse and build sustainable value chains will stand out in a market increasingly defined by responsibility and innovation.

7. AI and Machine Learning for Packaging Optimization

Artificial intelligence is reshaping packaging by enabling predictive analytics, image recognition, and real-time process optimization. AI-powered design tools are helping companies test new packaging configurations and simulate stress tests without physical prototyping.

Machine learning algorithms are being applied to demand forecasting, waste reduction, material selection, and even consumer preference prediction. These tools allow packaging professionals to streamline processes, reduce costs, and accelerate innovation cycles.

Integrating AI into packaging operations is not a luxury—it’s quickly becoming essential for companies aiming to maintain agility and responsiveness in 2025 and beyond.

8. Minimalism and Aesthetic Storytelling

Clean, uncluttered designs continue to dominate packaging shelves. Minimalist packaging focuses on essential messaging, clean lines, and premium finishes that reflect modern consumer tastes. This Packaging Trends 2025 movement is particularly resonant among Gen Z and Millennial shoppers who value transparency and authenticity.

At the same time, brands are using packaging as a medium for storytelling. Whether through graphics, typography, or material texture, packaging conveys brand values and connects with customers emotionally. When minimalism is combined with meaningful aesthetics, it results in a packaging experience that’s both functional and beautiful.

By focusing on visual storytelling and simplified design, companies can reduce visual noise and create stronger brand recognition across platforms.

9. Regulatory Compliance and Label Transparency

Governments are tightening regulations related to packaging waste, recycling rates, and product labeling. Packaging Trends 2025 highlight the importance of transparency, traceability, and legal compliance. Companies must stay up to date with regional and international guidelines to avoid fines and reputational damage.

Clear labeling of ingredients, recycling instructions, carbon footprint, and sourcing origin are becoming expectations rather than extras. Smart labels and QR codes are making it easier to convey detailed information without crowding the package design.

Compliance is no longer just a checkbox—it’s a strategic advantage that reinforces trust and aligns with conscious consumerism.

10. The Future of Packaging: Integrating All Trends

As the Packaging Trends 2025 converge, the future of packaging is intelligent, sustainable, and highly personalized. Leading companies are not choosing one trend—they are combining several to create holistic strategies that drive efficiency, enhance consumer engagement, and align with global sustainability goals.

Hybrid approaches—such as smart sustainable packaging with AI-optimized logistics—are emerging. Innovation hubs, cross-industry collaborations, and tech startups are accelerating the pace of change. For businesses to stay competitive, continuous learning, rapid prototyping, and adaptability are key.

Ultimately, the packaging leaders of 2025 will be those who integrate these trends with purpose, using packaging not just as a container, but as a strategic asset in delivering value to both the customer and the planet.

Conclusion: How Modern Machinee Supports Your Packaging Goals

Staying ahead in the world of packaging in 2025 requires a blend of innovation, agility, and strategic partnerships. Whether you’re exploring automation, aiming for sustainability, or personalizing your packaging, navigating these trends effectively calls for reliable and advanced solutions.

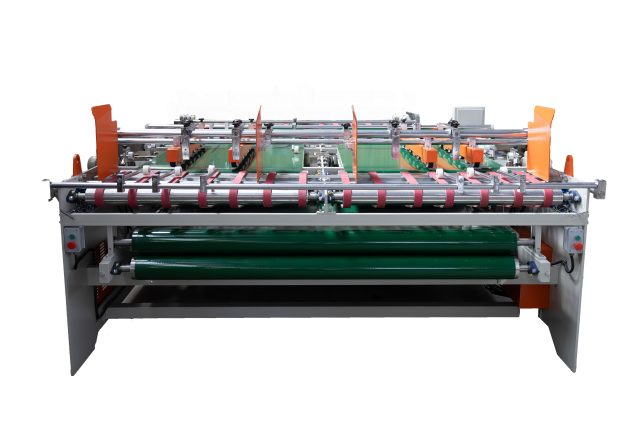

That’s where Modern Machinee comes in. With over a decade of experience in manufacturing high-performance packaging machinery—including Folder Gluers and advanced Two Sheet systems—Modern Machinee is equipped to help businesses of all sizes adapt to the latest Packaging Trends 2025. Our solutions are designed for precision, speed, and sustainability, giving you the edge in a highly competitive market.

From automated packaging lines to flexible customization options, our team offers hands-on support, tailored consulting, and cutting-edge machinery that grows with your business. As the packaging landscape evolves, Modern Machinee stands by you—ensuring your operations stay efficient, compliant, and future-ready.

Visit Modern Machinee to explore how our technology and expertise can transform your packaging operations in 2025 and beyond.