So, you’re thinking about starting a packaging line in 2025? Great choice! With the rise of e-commerce, local manufacturing, and small-scale product brands, packaging has never been more essential. Whether you’re a startup, small business, or upgrading from manual to automated systems, this guide is here to walk you through the entire process—from planning to purchasing your first machines.

Let’s get started.

Chapter 1: Why 2025 Is the Right Time to Start a Packaging Line

1.1 The Packaging Industry Boom

- E-commerce and direct-to-consumer businesses are thriving

- Sustainability is pushing for smarter packaging solutions

- More government incentives and support for local manufacturing

1.2 New Technologies = Better Opportunities

- Folder Gluers and other modern machines are more efficient and affordable

- Automation and AI integration reduce errors and costs

- Modular systems mean you can scale your setup over time

Chapter 2: Understanding the Basics of a Packaging Line

2.1 What Is a Packaging Line?

A packaging line is a series of machines and processes that prepare products for shipment. It usually includes:

- Folding & gluing machines (like Folder Gluers)

- Labelers

- Fillers & sealers

- Conveyors

- QC checkpoints

2.2 Manual vs. Semi-Automatic vs. Fully-Automated

| Type | Pros | Cons |

|---|---|---|

| Manual | Low upfront cost | Labor-intensive, slow |

| Semi-Automatic | Balance of cost and efficiency | Still needs human input |

| Fully-Automated | Fast, consistent, scalable | Higher investment needed |

Chapter 3: Planning Your Packaging Line

3.1 Define Your Product and Packaging Type

• Boxed goods, pouches, bottles, etc.

• Primary vs. secondary packaging

3.2 Set Your Budget (Realistically)

• Equipment (60%)

• Setup & layout (15%)

• Training & labor (15%)

• Maintenance & contingency (10%)

3.3 Calculate Expected Volume

• Daily production target

• Seasonal peaks

• Room for growth

3.4 Layout & Workflow Design

• Avoid bottlenecks

• Plan for operator space, safety zones, and maintenance access

Chapter 4: Choosing the Right Machinery

4.1 Folder Gluer Machines: The Heart of Carton Packaging

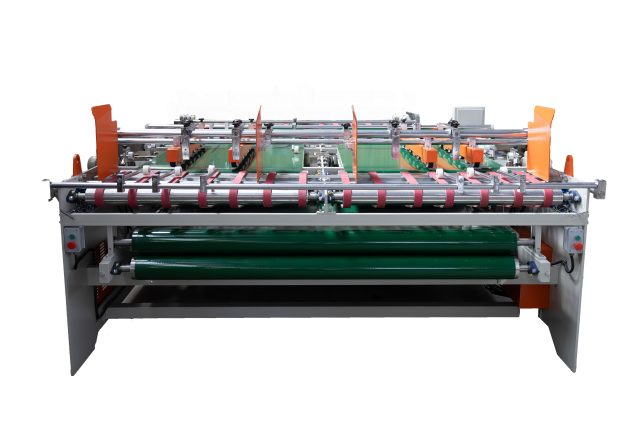

- Ideal for folding and gluing cardboard boxes

- Available in single-sheet and two-sheet configurations

Modern Machinee Tip: If you deal with larger or complex boxes, Semi automatic folder gluer (two lines) can save time and reduce labor costs.

The Semi-Automatic Double Sheets (A/B) machine represents a significant advancement in the folding and gluing of carton and box sheets.

4.2 Complementary Machines

- Conveyors

- Taping machines

- Label printers

- Barcode scanners

4.3 Scalability and Compatibility

- Choose modular machines that allow you to add more units later

- Ensure all machines can communicate (PLC systems)

Chapter 5: Sourcing Your Equipment

5.1 Buy New or Used?

- New: Latest tech, warranty, training included

- Used: Lower cost, but higher risk

5.2 Where to Buy

- Trusted manufacturers (like Modern Machinee)

- Trade shows

- Industry marketplaces (e.g., Exapro, Machineseeker)

5.3 Questions to Ask Vendors

- What’s the warranty?

- What support do you offer?

- How many operators are needed?

- Is installation included?

Chapter 6: Installation, Training, and Testing

6.1 Site Preparation

- Power supply and air compressors

- Internet connectivity (for smart devices)

- Climate and humidity control

6.2 Staff Training

- Don’t just teach operation—teach maintenance and troubleshooting

6.3 Dry Runs & Testing

- Run a batch without products to identify issues

- Fine-tune settings for speed, glue amount, alignment, etc.

Chapter 7: Running and Maintaining Your Line

7.1 Daily Operations

- Pre-start checks

- Operator logs

- Shift change protocols

7.2 Maintenance Schedule

- Weekly: Cleaning, lubrication

- Monthly: Component checks

- Quarterly: Full system diagnostics

Pro Tip: Schedule downtime for preventive maintenance to avoid sudden breakdowns.

7.3 Tracking and Improving Performance

- Use KPIs: output per hour, reject rate, uptime %

- Consider using software for production analytics

Chapter 8: Marketing Your Packaging Services (If B2B)

8.1 Build a Website and Portfolio

- Show machine photos, sample packaging

- Add case studies

8.2 Attend Industry Events

- Networking at expos and trade shows

8.3 Offer Custom Solutions

- Sustainability packaging?

- Short-run prototypes?

Chapter 9: Trends to Watch in 2025

9.1 Smart Packaging

- NFC chips

- QR tracking

9.2 Eco-Friendly Materials

- Compostable films

- Recycled cardboard

9.3 AI and Robotics

- Vision-based sorting

- Predictive maintenance

Final Thoughts

Starting a packaging line in 2025 isn’t just a good business move—it’s a smart step toward future-proofing your operations. With the right planning, right equipment, and a little help from trusted partners like Modern Machinee, you’ll be up and running in no time.

Need help choosing your first Folder Gluer? Reach out—we’re happy to assist!

Modern Machinee can help you every step of the way—from choosing your first Folder Gluer to optimizing your entire packaging workflow. Reach out to our team for expert guidance and custom solutions tailored to your production needs